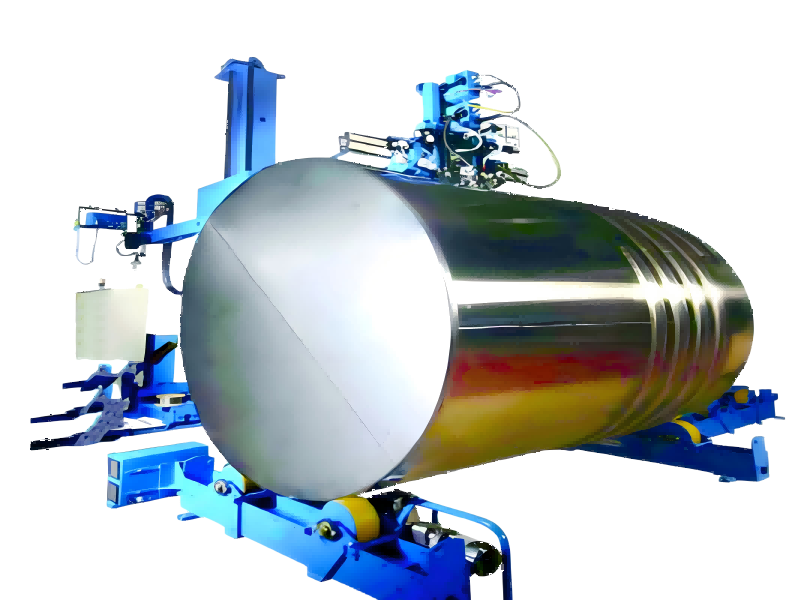

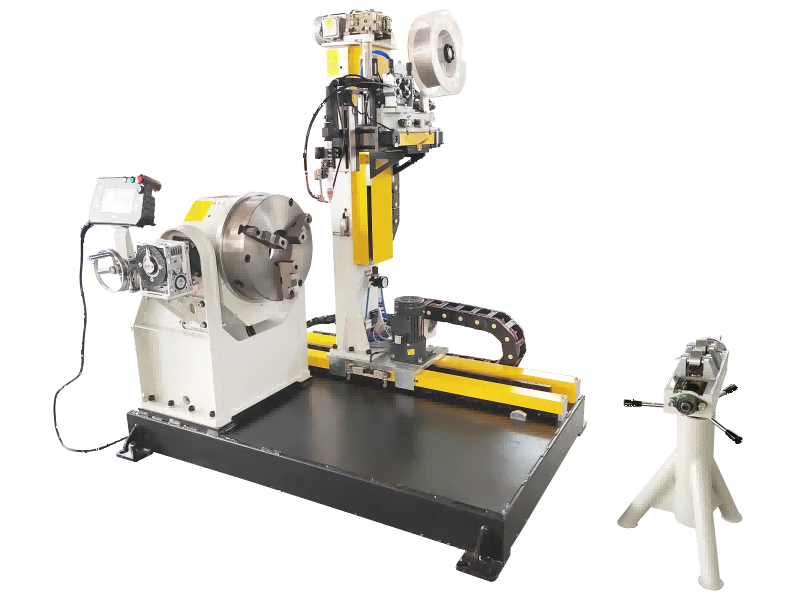

MWZF‑2000 Automatic TIG MIG Welder

Product Type: Longitudinal Seam Welding Machine

The MWZF‑2000 is a medium‑duty longitudinal seam welding system specialized for stainless steel, titanium, and aluminum alloy components. Supporting TIG, MIG, MAG, and PAW processes, it delivers high weld consistency, precise seam alignment, and automated control for shell thickness up to 12 mm. Ideal for pressure vessels, heat exchangers, and pipeline fabrication industries.

Product Features:

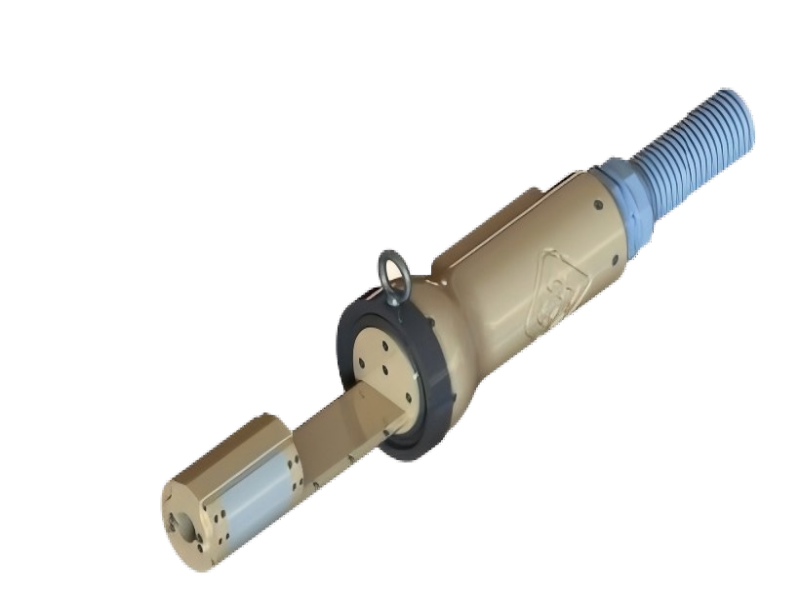

Supports multiple welding processes: TIG, MIG, MAG, and PAW.

Handles workpieces up to 2000 mm length and 12 mm thickness.

Equipped with Siemens‑based automation and efficient heat dissipation design.

Overview

The MWZF‑2000 longitudinal seam welder provides automated, high‑precision joining for medium‑sized cylindrical shells made of stainless steel, titanium, or aluminum alloys. Designed for industrial manufacturing, it ensures consistent weld quality and process stability.

Integrated with digital control, Siemens automation, and advanced cooling systems, it supports TIG, MIG, MAG, and PAW welding methods. The unit achieves superior seam accuracy and repeatability across varied joint geometries.

Covers weld length up to 2000 mm with 12 mm maximum thickness.

Multi‑process versatility for TIG, MIG, MAG, and PAW applications.

Enhanced automation and real‑time parameter monitoring.

Specification

Product Name

Model

Longitudinal Seam Welder

MWZF-2000

Max. Welding Length (Single Circular, mm)

1600

Max. Welding Length (Double Circular, mm)

2000

Max. Workpiece Length (mm)

2100

Max. Workpiece Diameter (OD, mm)

1100

Min. Chuck Diameter (OD, mm)

Φ180 (round) / Φ330 (square)

Min. Wall Thickness (mm)

1.0

Max. Wall Thickness (mm)

12

Travel Speed (mm/min)

60–1200

Max. Travel Stroke (mm)

2200

Benefits & Features

01

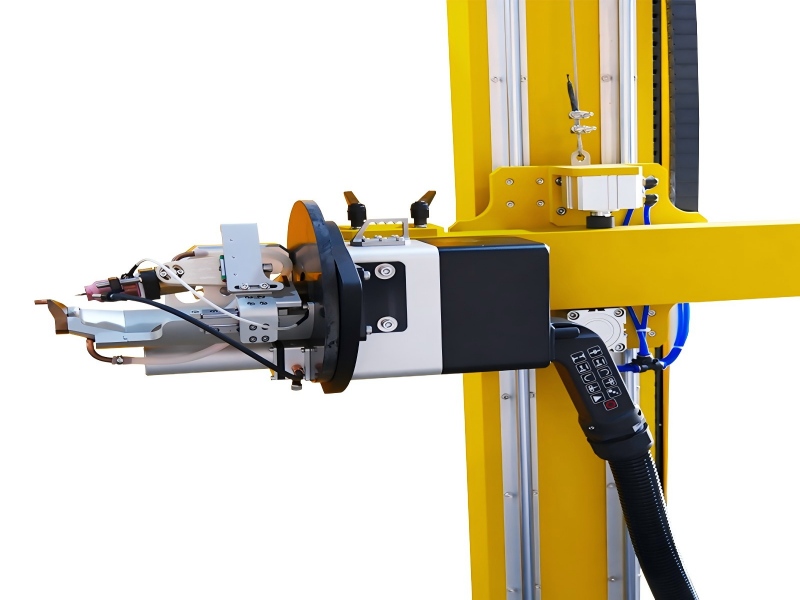

High‑Precision Seam Control

Advanced servo positioning and seam tracking systems ensure consistent weld alignment, minimizing deformation and achieving superior surface finish for cylindrical shells and flat panels.

02

Multi‑Process Compatibility

Supports TIG, MIG, MAG, and PAW welding modes, enabling flexibility across materials such as stainless steel, titanium, and aluminum alloys — ideal for diverse production environments.

03

Optimized Automation

Equipped with Siemens programmable control, the MWZF‑2000 automates welding parameters, sequence timing, and power adjustment, increasing efficiency and repeatability.

04

Industrial‑Grade Reliability

Durable mechanical structure combined with efficient cooling and stable current management ensures 24/7 industrial operation under demanding production conditions.

Application

The MWZF‑2000 longitudinal seam welding system is widely applied in manufacturing processes requiring precision, repeatability, and durable weld seams. It serves industries where consistent longitudinal joint quality directly impacts product safety and performance.

Pressure vessel and storage tank manufacturing

Heat exchanger and condenser tube production

Pipeline, aerospace, and chemical equipment fabrication

FREQUENTLY ASKED QUSTIONS

Frequently Asked Questions about MWZF‑2000 Operation & Integration

Our engineers have compiled the most common inquiries regarding installation, welding compatibility, and maintenance of the MWZF‑2000 system. This section helps users ensure smooth startup and optimal performance across industrial environments.

Technical Engineer Team , ikratz Welding Systems

What welding processes are supported by MWZF‑2000?

The system supports TIG, MIG, MAG, and PAW processes, providing flexibility for stainless steel, aluminum, and titanium materials.

Does it integrate with existing plant automation?

Yes. The Siemens‑based controller can link with factory PLCs and data networks for seamless automation and quality tracking.

What are the maintenance requirements?

Routine inspection of the clamping mechanism, cooling circuits, and electrode surfaces is recommended every 500 hours for optimal performance.