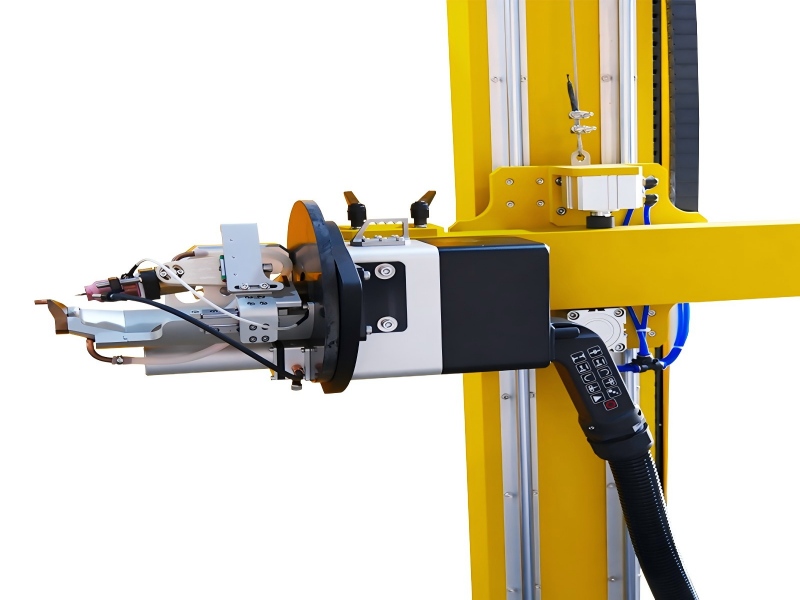

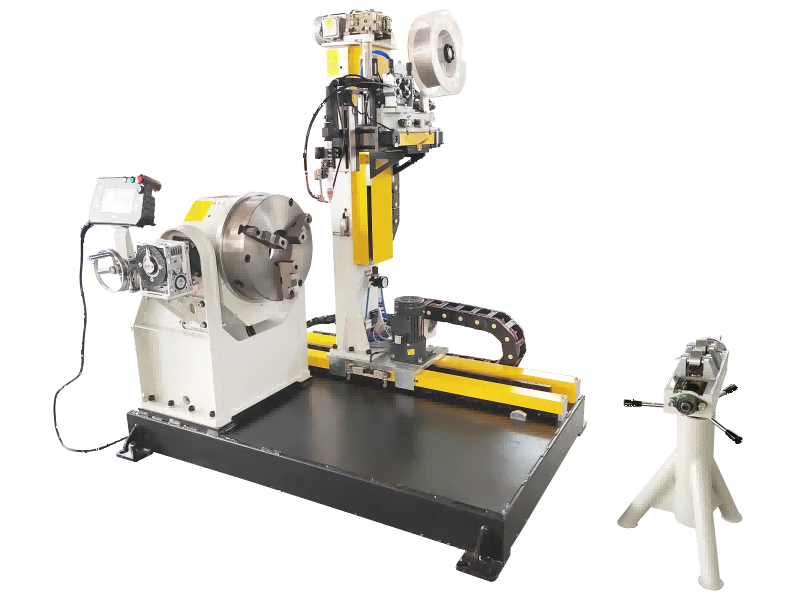

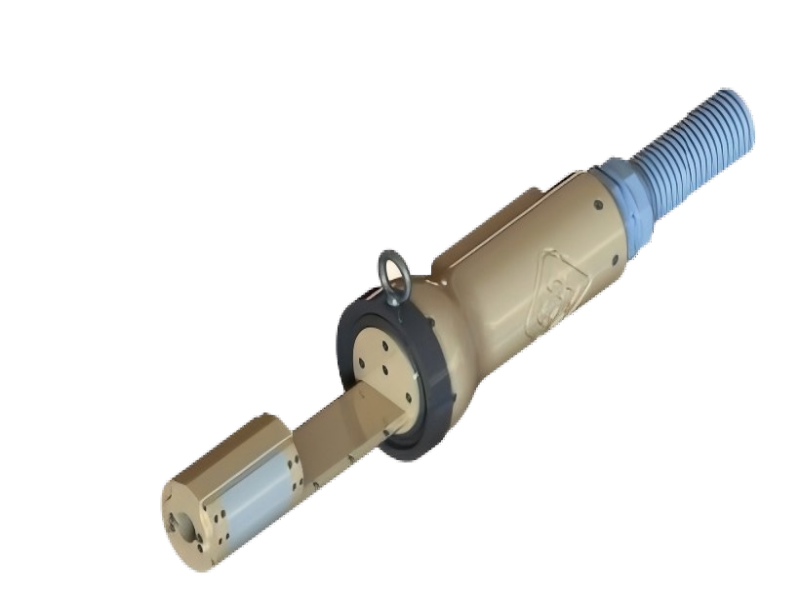

MWP-65C Tube Sheet Welding Machine

Product Type: All-position Tubesheet Welder

The MWP-65C delivers precise, automatic tube-to-tubesheet welding across all positions. Featuring advanced power control, efficient water cooling, and compatibility with carbon steel, stainless steel, titanium, and nickel alloys, it ensures stable performance, consistent weld quality, and higher productivity in heat exchanger and petrochemical manufacturing.

Product Features:

Full-position automatic welding capability

Wide material compatibility (steel, stainless, titanium, nickel alloys)

Stable power control with advanced water-cooling system

Overview

The MWP-65C is a full-position automatic tube-to-tubesheet welding machine designed for heat exchangers, condensers, and pressure vessels. With advanced welding control and efficient cooling, it provides stable performance and exceptional precision.

Engineered for demanding industrial environments, MWP-65C supports diverse materials including carbon steel, stainless steel, titanium, and nickel alloys, ensuring superior weld strength and consistent quality in power, petrochemical, and manufacturing applications.

Precise all-position welding performance

Reliable operation with water-cooling system

Supports a wide range of metals

Specification

Product Name

Model

All-position Tubesheet Welder

MWP-65C

Applicable Tube Size

ID Φ6 – OD Φ63

Wire Diameter (mm)

Φ0.8 / Φ1.0

Shielding Gas

Argon

Cooling Method

Water-cooled

Tungsten Electrode (mm)

2.4

Welding Head Weight (kg)

8

Benefits & Features

01

High Welding Precision

Advanced control system ensures consistent weld penetration, strength, and quality, reducing rework and improving reliability in critical tube-to-tubesheet projects.

02

Wide Material Compatibility

Supports carbon steel, stainless steel, titanium, and nickel alloys, offering maximum flexibility for diverse industrial applications.

03

Increased Productivity

Automatic full-position welding shortens cycle time, stabilizes processes, and boosts production efficiency for heat exchangers and pressure vessels.

04

Reliable Cooling Technology

Integrated water-cooling system enhances machine stability, prevents overheating, and extends operational life in demanding environments.

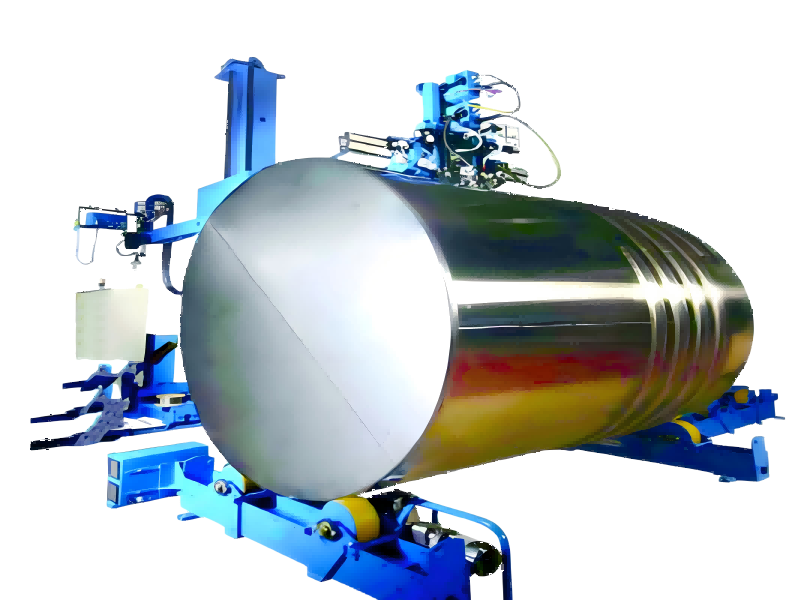

Application

The MWP-65C is ideal for automated tube-to-tubesheet welding across diverse industries. It delivers reliable performance for equipment requiring strong, leak-proof joints such as heat exchangers, boilers, and condensers. With its versatility and precision, it ensures long-term safety and efficiency in industrial operations.

Heat exchangers and condensers in power & energy plants

Pressure vessels and reactors for petrochemical industry

Industrial boilers, coolers, and HVAC equipment manufacturing

FREQUENTLY ASKED QUSTIONS

Frequently Asked Questions (MWP-65C Tube-to-Tubesheet Automatic Welding Machine)

Our expert team answers the most common customer questions to help you better understand the MWP-65C in industrial applications.

Senior Welding Engineer, Ikratz

What materials can the MWP-65C weld?

The machine supports carbon steel, stainless steel, titanium, and nickel alloys, meeting the needs of industries like power, petrochemical, and HVAC.

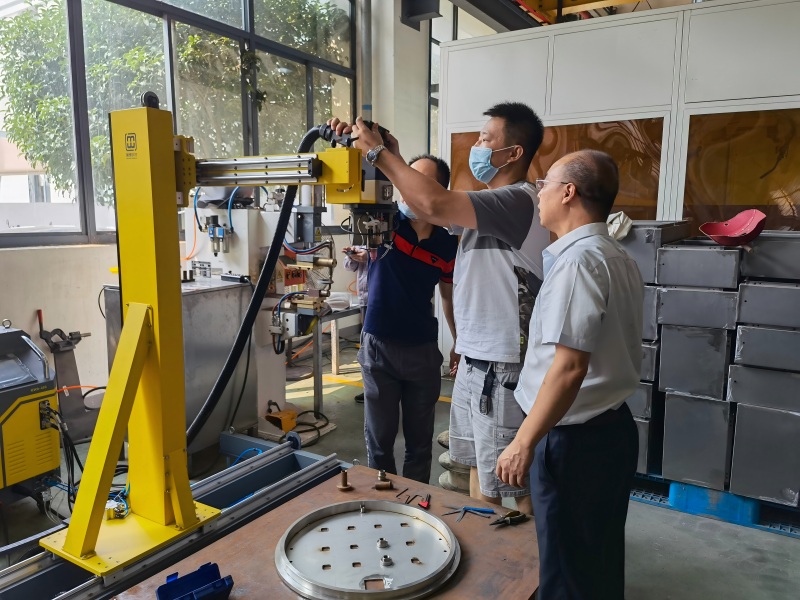

Do operators need special training?

The system is user-friendly and requires minimal training. Basic welding knowledge is enough, while Ikratz provides full setup and operation support.

Can it handle different tube sizes?

Yes, the MWP-65C accommodates a wide range of tube diameters and thicknesses, making it highly versatile for various projects.