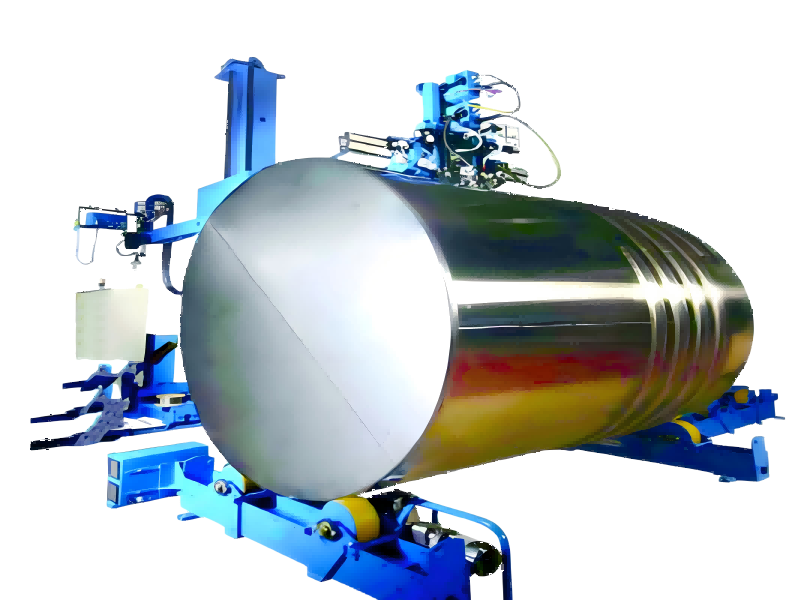

Hot Wire Surfacing Welding System

Product Type: Automatic TIG Overlay Welding Equipment

Designed for high‑precision overlay welding, this system enhances wear and corrosion resistance of parts such as pipes, valves, and fittings. Featuring Siemens or Mitsubishi control, it integrates Fronius, EWM, or Miller power sources to ensure stable arc performance, uniform deposition, and efficient automation for industrial surfacing operations.

Product Features:

Dual‑mode vertical or horizontal operation

Compatible with stainless steel and nickel alloys

High‑efficiency automated TIG hot‑wire process

Overview

The Hot Wire Surfacing Welding System provides advanced TIG overlay for extending component life and improving corrosion and wear resistance. Designed for precision industrial repair and manufacturing, it delivers consistent deposition quality through intelligent control and optimized heat input.

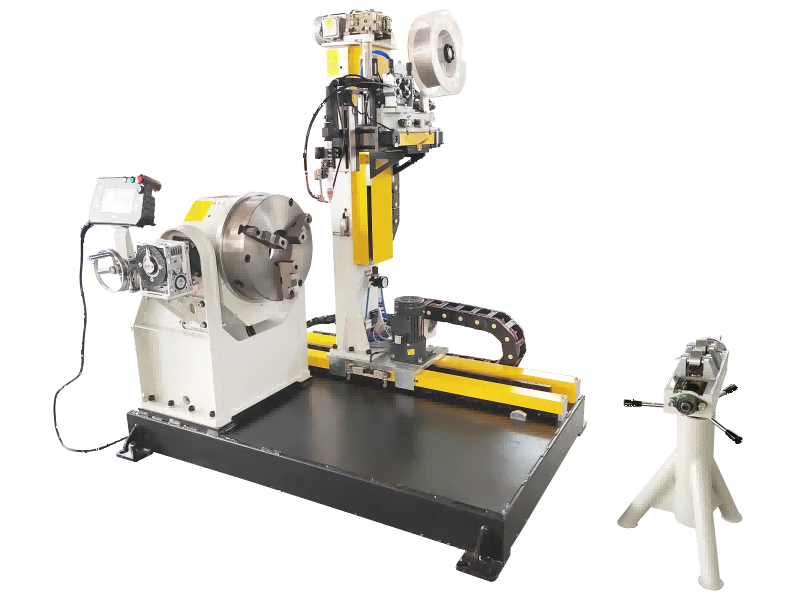

Integrated with Siemens or Mitsubishi control systems, the equipment supports automated operations for pipes, valves, and fittings. Its modular design ensures easy customization for vertical, horizontal, or dual‑station setups.

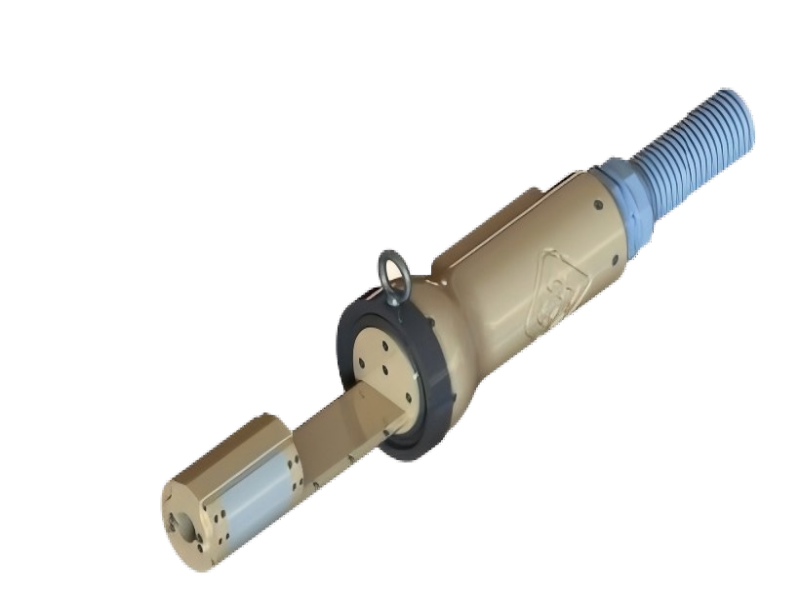

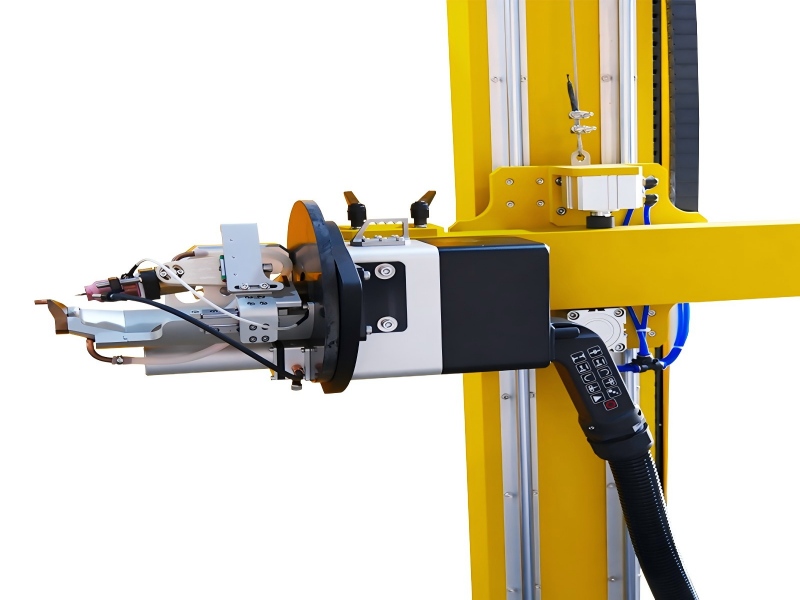

High‑precision automated TIG hot‑wire process

Supports stainless steel and nickel‑based alloys

Customizable configuration for multiple workpiece types

Specification

Product Name

Model

Hot Wire Surfacing Welding System

Applicable Materials

Suitable for pipe and fitting welds (flange, three‑way, elbow) as well as inner and outer circumferential seams

Welding Type

Suitable for pipe and fitting welds (flange, three‑way, elbow) as well as inner and outer circumferential seams

Optional Power Sources

Fronius, EWM, REHM , Miller , OTC and other equivalent brands

Main Control System

SIEMENS , Mitsubishi , XINJE and compatible industrial controllers

Benefits & Features

01

Enhanced Welding Efficiency

Hot‑wire TIG technology increases deposition rate and productivity while maintaining stable arc control and precise heat management, ideal for continuous surfacing applications.

02

Superior Surface Quality

Produces smooth, uniform overlays with excellent metallurgical bonding, improving component durability and reducing post‑processing requirements.

03

Flexible System Integration

Supports customization for vertical, horizontal, or dual‑station configurations with Siemens/Mitsubishi control and Fronius, EWM, or Miller power sources.

04

Reduced Operational Cost

Optimized energy use, wire feeding, and automation reduce material waste and labor time, ensuring long‑term cost efficiency for industrial users.

Application

The Hot Wire Surfacing Welding System is engineered for precision overlay welding across various industrial sectors. It enhances part durability and performance in harsh working environments by delivering consistent, defect‑free weld surfaces with superior metallurgical properties.

Oil & Gas – Pipeline, valve, and drilling tool surfacing

Petrochemical – Reactor and heat‑exchanger component repair

Power Generation – Turbine, shaft, and pump housing hardfacing

FREQUENTLY ASKED QUSTIONS

Frequently Asked Questions

Key answers for Hot Wire Surfacing Welding System

Tech Support Team,iKratz

What materials can the system weld?

It supports stainless steel, Inconel, Hastelloy, and other nickel‑based alloys commonly used in high‑corrosion or high‑temperature environments.

Can the equipment be customized for different workpieces?

Yes. The modular design allows configuration for pipe, valve, or flat‑plate operations, including vertical, horizontal, and dual‑station options.

What control systems are compatible?

The system integrates seamlessly with Siemens or Mitsubishi CNC controllers and supports Fronius, EWM, or Miller power sources.