Smart & Flexible Custom Automation Solutions

Empower your business with fully customized automation systems that boost efficiency, enhance precision, and adapt seamlessly to your unique production needs.Contact Now!

Custom Automation Solutions

Custom Automation Solutions

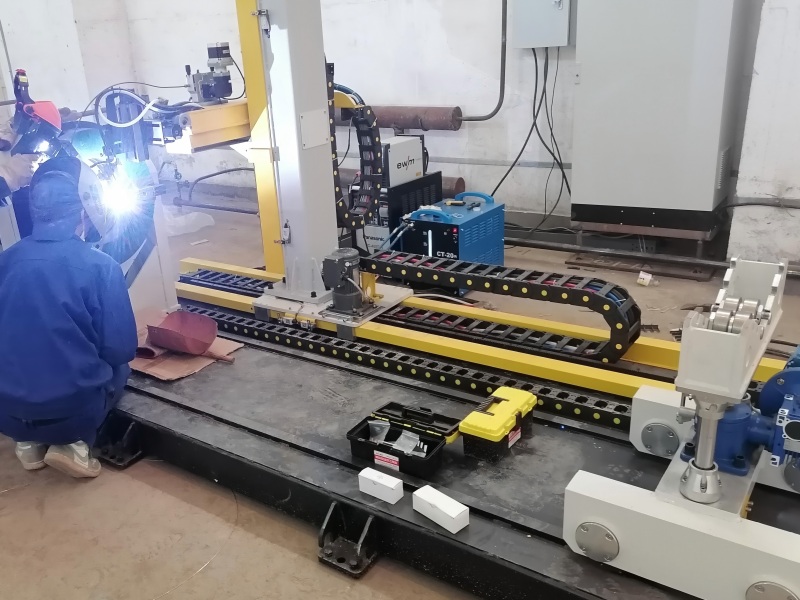

Automatic Plasma Welding Equipment

MWZF-2000 seam automatic welding equipment

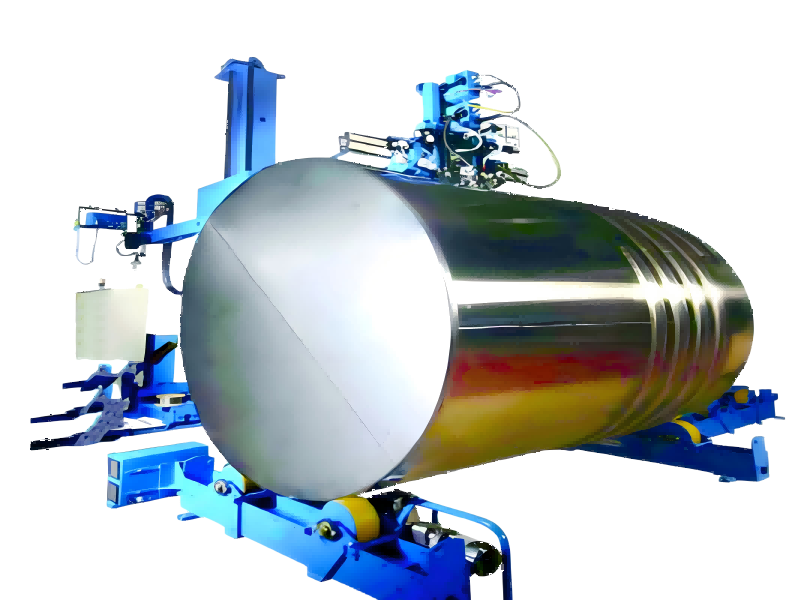

MWHF-HL Circumferential Seam Welding System

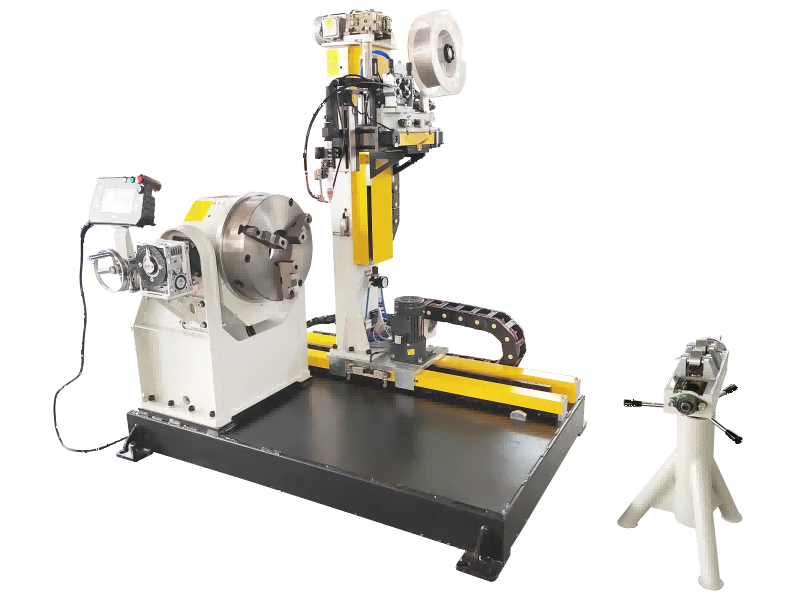

MWHF-HM Seam Welding Machine System

MWHF-ZM TIG Seam Welding System

Custom Automation Solutions. Tailored for Your Success.

Core Advantages of Our Welding Automation Equipment

Designed to meet the most demanding industrial requirements, our solutions combine flexibility, precision, and durability—empowering manufacturers to achieve flawless results at scale.

Versatile Material Compatibility

Supports carbon steel, stainless steel, aluminum alloys, copper alloys, and other metals. Ideal for pipes, elbows, flanges, and various cylindrical workpieces.

Advanced Automation Control

Equipped with speed regulation, power control, gas-shield systems, and integrated cooling solutions—ensuring 24/7 stable operations with minimal downtime.

Customizable Efficiency

Flexible modular design with adjustable swing angles, travel distances, and welding processes (TIG, MIG, MAG, PAW) tailored to specific production needs.

Core Advantages of Our Welding Automation Equipment

Designed to meet the most demanding industrial requirements, our solutions combine flexibility, precision, and durability—empowering manufacturers to achieve flawless results at scale.

Versatile Material Compatibility

Advanced Automation Control

Customizable Efficiency

Applications of Welding Automation Solutions

Our circumferential and longitudinal seam welding machines are widely applied across industries that require high-precision, consistent, and durable welds. From heavy-duty pipelines to delicate medical equipment, our systems ensure superior results that meet international quality standards.

About Custom Automation Solutions

Custom Automation Solutions specializes in designing and manufacturing advanced automatic welding machines, including circumferential and longitudinal seam welding solutions. With years of expertise, we serve industries such as pressure vessels, pipelines, automotive, aerospace, and medical equipment manufacturing. Our mission is to provide flexible, precise, and reliable automation systems that help manufacturers improve efficiency, ensure top-quality welding results, and reduce production costs.

Success Stories with Custom Automation Solutions

Our customized automation systems have helped clients across industries improve efficiency, enhance precision, and lower production costs. Here’s what they say:

How We Work Together

Our streamlined 3-step process ensures you receive the right automation solution—efficiently, reliably, and tailored to your needs.

01

02

03

Frequently asked questions

Unlike off-the-shelf machines, our solutions are fully tailored to your production needs. We design, engineer, and manufacture systems that integrate seamlessly into your existing workflow—ensuring higher efficiency and lower downtime.

You can begin by sharing your goals, production challenges, and technical requirements with us. Our engineers will then provide a feasibility review, proposal, and quotation tailored to your operations.

Yes. We provide operator training, installation guidance, and ongoing technical support. Our systems are also covered by a 12-month warranty with lifetime service support.