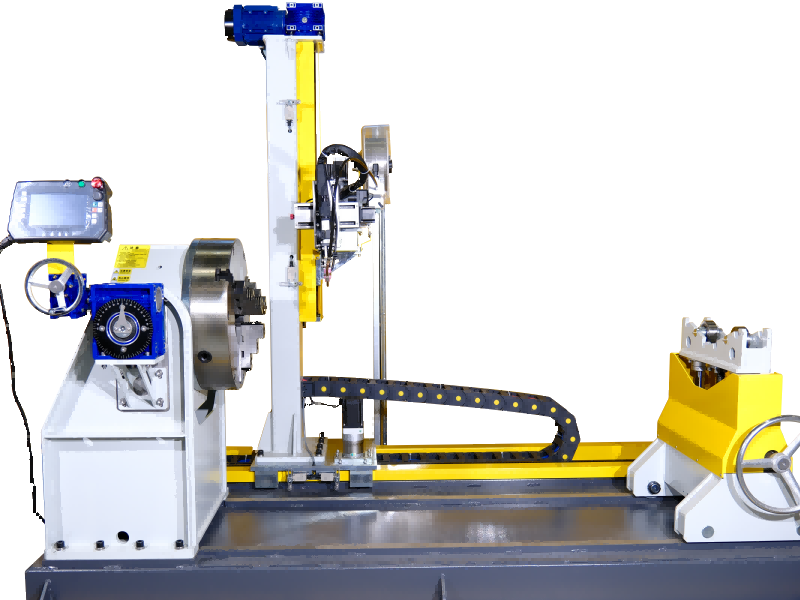

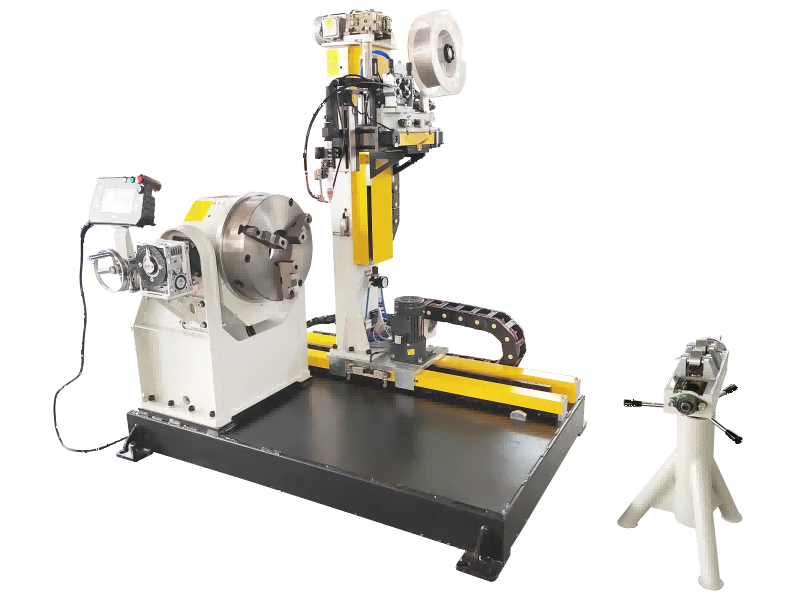

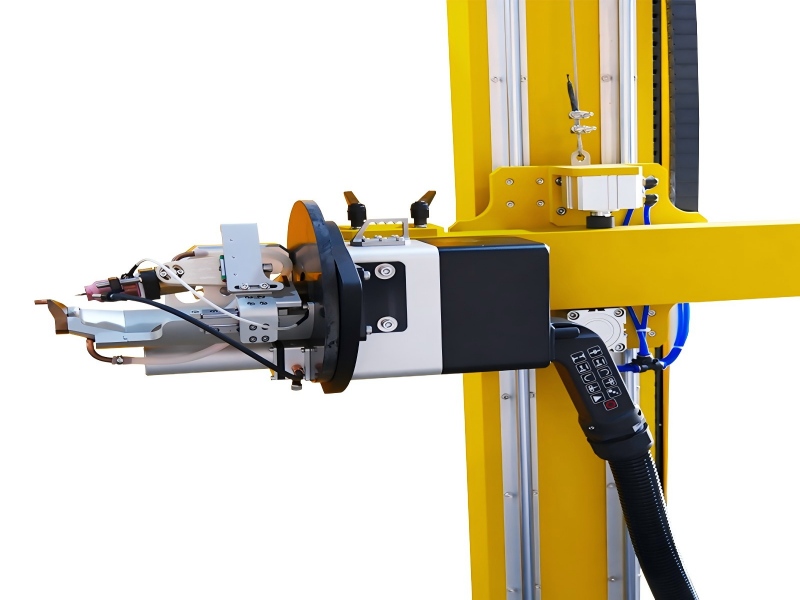

MWHF‑HL Circumferential Hot Wire Welding System

Product Type: Automatic TIG / Hot Wire Cladding System

High‑precision hot wire TIG welding system for circumferential joints. Ensures stable penetration, smooth weld seams, and high deposition efficiency. Ideal for stainless steel, Inconel, and titanium components in petrochemical, energy, and aerospace industries.

Product Features:

High‑efficiency hot‑wire TIG process for superior weld quality

Multi‑axis servo motion with full digital parameter control

Modular design supports quick tooling change and MES integration

Overview

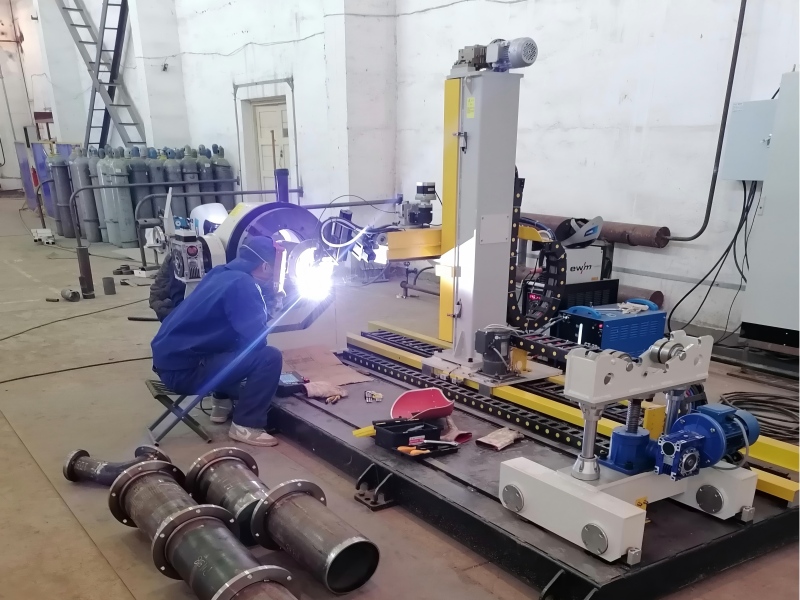

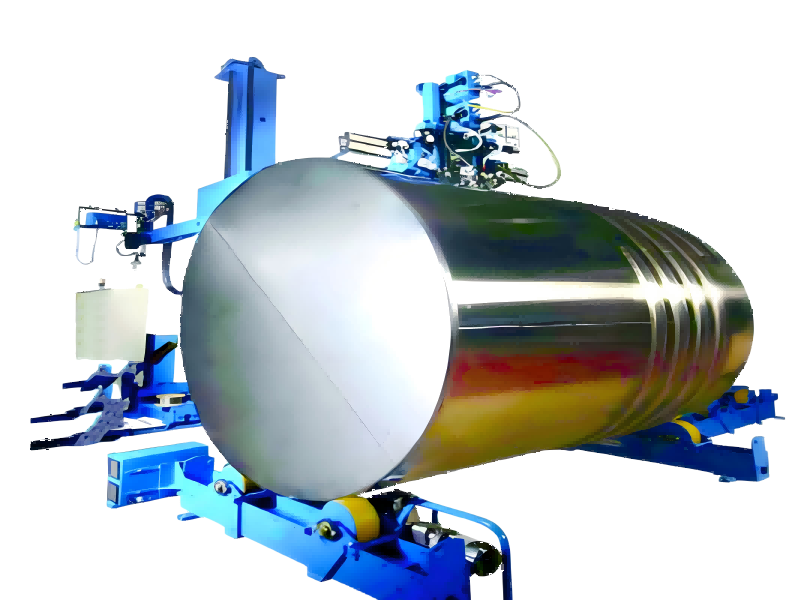

The MWHF‑HL horizontal circumferential welding system is engineered for the automated welding of cylindrical parts, tanks, and pressure vessels. It combines precision motion control with robust mechanical design to ensure high weld quality and repeatability.

Equipped with digital monitoring and adaptive control, it provides stable performance across TIG, MIG, and MAG processes—ideal for stainless steel, titanium, and heat‑resistant alloys used in aerospace, energy, and industrial manufacturing.

High‑accuracy rotation and torch positioning.

Supports multiple welding modes and material types.

Digital interface for consistent process control and traceability.

Specification

Product Name

Model

Seam Welding Machine

MWHF-HL

Applicable Workpiece Diameter

Φ50~500

Welding Torch Travel

0~3000 (customizable)

Spindle Rotation Speed

0.1~2 rpm

Chuck Vertical Travel

250 (electric)

Vertical Electric Slide Travel

0~500 (customizable)

Moving Carriage Travel

0~3000 (customizable)

Boom Extension/Oscillation Travel

±50

Load Capacity (kg)

1200

Benefits & Features

01

High‑Precision Rotary System

Advanced motorized chuck ensures steady, concentric rotation for precise circumferential welding, delivering consistent joint quality even on large or asymmetric components.

02

Extended Arm Travel

Long‑stroke welding arm supports wide‑range motion, allowing flexible setup and easy adaptation to various heat‑exchanger diameters and configurations.

03

Smart Control Interface

Integrated digital control panel enables programmable welding parameters, multi‑layer sequencing, and real‑time monitoring for optimal process efficiency.

04

Modular Integration Design

Compatible with other MWHF units for multi‑station expansion; the modular structure simplifies maintenance and line upgrading while minimizing downtime.

Application

The MWHF‑ML system is engineered for automated circumferential welding of heat exchangers, pressure vessels, and tube assemblies. It delivers stable high‑precision joints in industries requiring consistent weld quality and efficiency in repetitive multi‑layer welding processes.

Heat Exchanger Manufacturing

Pressure Vessel Fabrication

Chemical & Power Equipment Welding

FREQUENTLY ASKED QUSTIONS

Frequently Asked Questions

Our technical team answers the most common customer questions about i the MWHF-HL

Welding Engineer Team , ikratz

What type of welding work is the MWHF‑HL designed for?

It’s optimized for horizontal seam welding on large heat exchangers and heavy cylindrical shells.

Does it support automation or robotic integration?

Yes, the HL model offers PLC and robotic interface compatibility for automated production lines.

Can welding parameters be customized?

Absolutely. All major parameters—speed, current, and torch position—are programmable via the touch control interface.