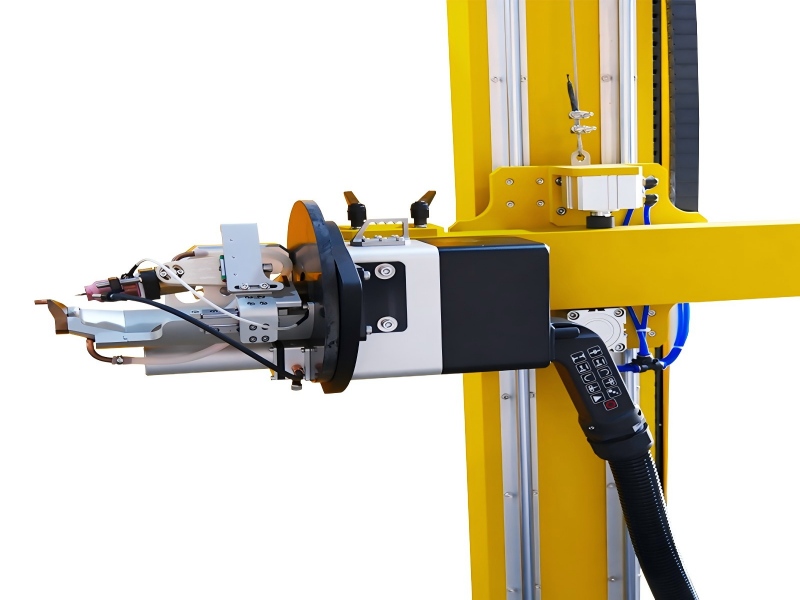

Tube Sheet Welding Systems: Precision for Critical Applications

Engineered for flawless tube - to - sheet welds in heat exchangers, pressure vessels, and industrial equipment. Our systems deliver consistent, regulation - compliant performance to power your most demanding projects. Contact Now!

Tube Sheet Welding Systems Collection

Tube Sheet Welding Systems Collection

MWP-65C Small Tube Sheet Welding Machine

MWP-65 Tube-to-Tubesheet Welding System

MWP-38 Tube-to-Tubesheet Welding System

Get Your Tube Sheet Welding Solution

Advanced Tube Sheet Welding System Features

Explore the core features that make our tube sheet welding systems deliver precision, efficiency, and reliability for critical industrial applications (like heat exchangers, pressure vessels, and pharmaceutical equipment).

Ultra - Precise Orbital Welding

Uses advanced orbital motion technology to create uniform, high - integrity welds on tube - sheet assemblies. This ensures minimal leakage, optimal thermal transfer, and compliance with strict industry standards (e.g., ASME, ISO).

Automated Efficiency & Speed

Integrates automated parameter control and rapid setup to reduce manual work, accelerate production cycles, and maintain consistent quality — even for high - volume tube sheet manufacturing.

Contamination - Resistant Design

Enclosed welding chambers and sterile - process compatibility keep external contaminants out, making these systems perfect for industries like pharmaceuticals, food processing, and aerospace that demand ultra - clean tube - sheet joints.

Advanced Tube Sheet Welding System Features

Explore the core features that make our tube sheet welding systems deliver precision, efficiency, and reliability for critical industrial applications (like heat exchangers, pressure vessels, and pharmaceutical equipment).

Ultra - Precise Orbital Welding

Automated Efficiency & Speed

Contamination - Resistant Design

Tube Sheet Welding in Critical Industries

Our tube sheet welding systems enable precise, efficient, and reliable welding for tube to sheet assemblies across key sectors. From pharmaceutical - grade purity to heavy - duty industrial thermal systems, these solutions meet strict industry standards and drive optimal performance in applications like heat exchangers, pressure vessels, and sterile processing equipment.

Leaders in Tube Sheet Welding Innovation

We’ve been dedicated to developing advanced tube sheet welding solutions for over a decade. Focused on precision, reliability, and user – friendliness, we serve industries like pharmaceuticals, energy, and manufacturing. By combining innovative engineering with deep industry knowledge, we help clients tackle complex welding challenges and improve production efficiency.

Customer Success with Tube Sheet Welding Systems

Hear from industry leaders who have transformed their tube - to - sheet welding processes with our advanced systems. Their experiences highlight the precision, efficiency, and reliability our technology delivers across critical applications.

Partner with Us for Advanced Welding Solutions

We offer flexible collaboration models to help businesses integrate cutting - edge tube sheet welding and orbital welding technologies into their operations. Whether you’re a manufacturer, distributor, or seeking customized welding solutions, we’re committed to co - creating value and driving success together.

01

02

03

Frequently asked questions

Our tube sheet welding systems serve multiple industries with strict requirements, including pharmaceuticals (for sterile processing equipment), energy (e.g., heat exchangers in power plants), chemical processing (for corrosion – resistant vessel fabrication), and general manufacturing (where precision tube – to – sheet joints are critical).

Precision is enabled by advanced orbital welding technology. Our systems use automated parameter control to maintain consistent weld profiles and high – precision motion mechanisms to ensure uniform tube – to – sheet fusion. This delivers reliable, leak – free joints that meet standards like ASME and ISO.

We offer comprehensive after – sales support: on – site installation/training for your team, regular maintenance, prompt technical troubleshooting, spare parts access, and upgrade consultations to keep your systems aligned with evolving tech and industry needs.