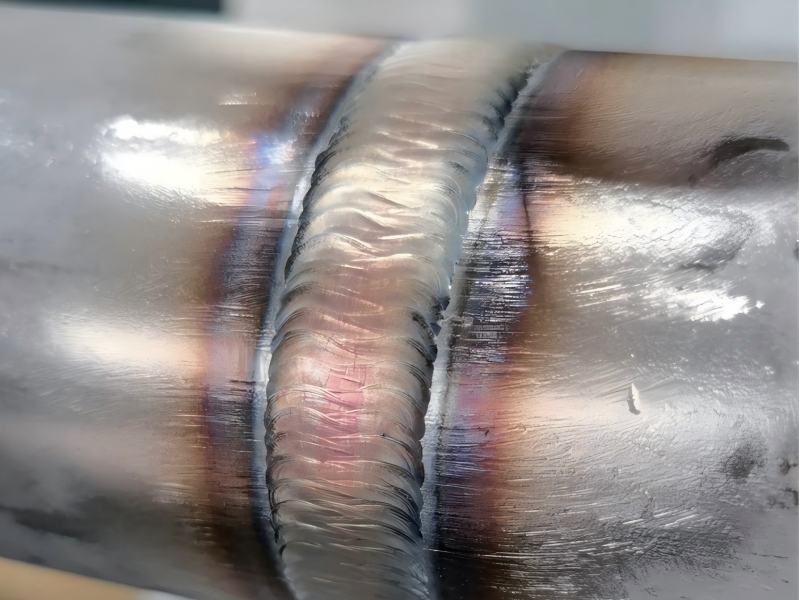

Ultra-Clean, Oxidation-Free Welds

Closed welding heads and controlled argon shielding create inert conditions around every joint, preventing discoloration and oxidation. The result: flawless weld integrity and zero particulate contamination in UHP pipelines.