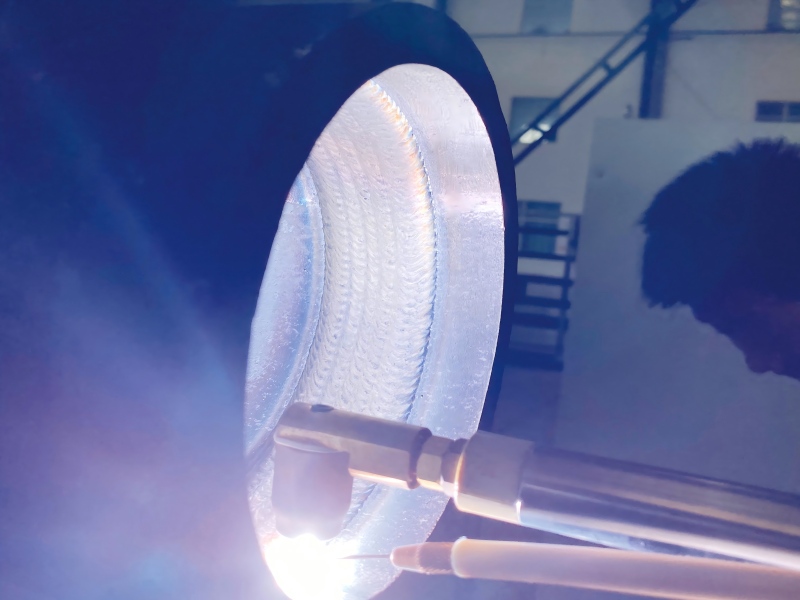

Automated Orbital Welding Systemm

Our orbital welding machines feature automated torch control, digital precision, and real‑time data monitoring—reducing labor costs and ensuring weld consistency across complex pipe diameters and materials.

Our precision orbital welding systems and automated fabrication solutions ensure reliable, high‑integrity joints across the most demanding offshore and cryogenic environments—delivering efficiency, safety, and durability for global energy projects.

Our orbital welding machines feature automated torch control, digital precision, and real‑time data monitoring—reducing labor costs and ensuring weld consistency across complex pipe diameters and materials.

Designed for cryogenic LNG applications, every weld remains structurally sound at ‑162 °C. The result: superior leak prevention, extended service life, and maximum system safety for offshore and onshore projects.

Designed for cryogenic LNG applications, every weld remains structurally sound at ‑162 °C. The result: superior leak prevention, extended service life, and maximum system safety for offshore and onshore projects.

From offshore platforms to cryogenic LNG terminals, our welding systems are trusted by world‑class EPC firms, shipyards, and process‑piping specialists who demand flawless performance and verifiable weld quality in every joint.

We specialize in orbital welding automation for LNG, pressure vessel, and offshore projects.

With years of engineering experience, we focus on precision, reliability, and safety in every weld.

All systems comply with ASME IX and ISO standards, ensuring consistent quality and global acceptance.

Our mission is simple — make every weld smarter, faster, and stronger.

Our welding automation systems are widely used in LNG, pressure vessel, offshore, and pipeline projects — wherever precision and reliability are critical.

Yes. Every project is different — we design and build systems tailored to your pipe size, material, and production needs.

Absolutely. We provide full installation guidance, operator training, and lifetime technical support to ensure stable operation.