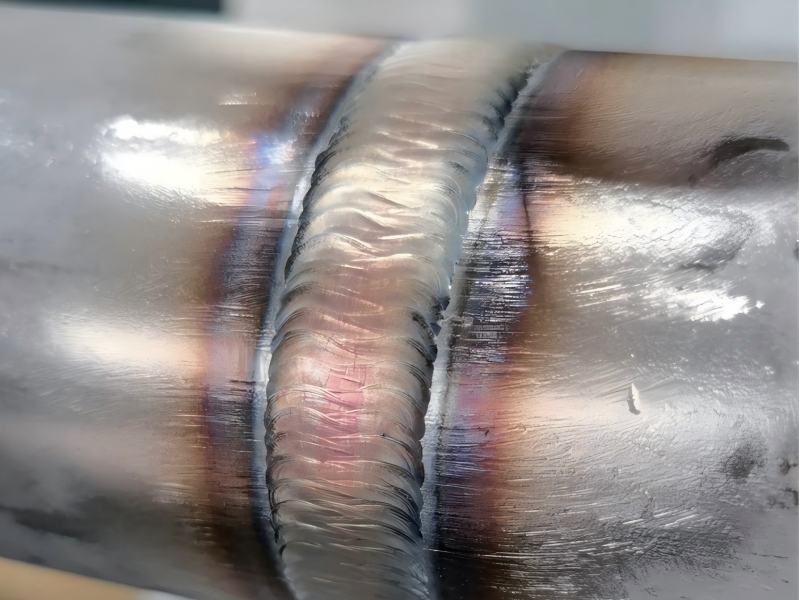

Automated Orbital Welding Precision

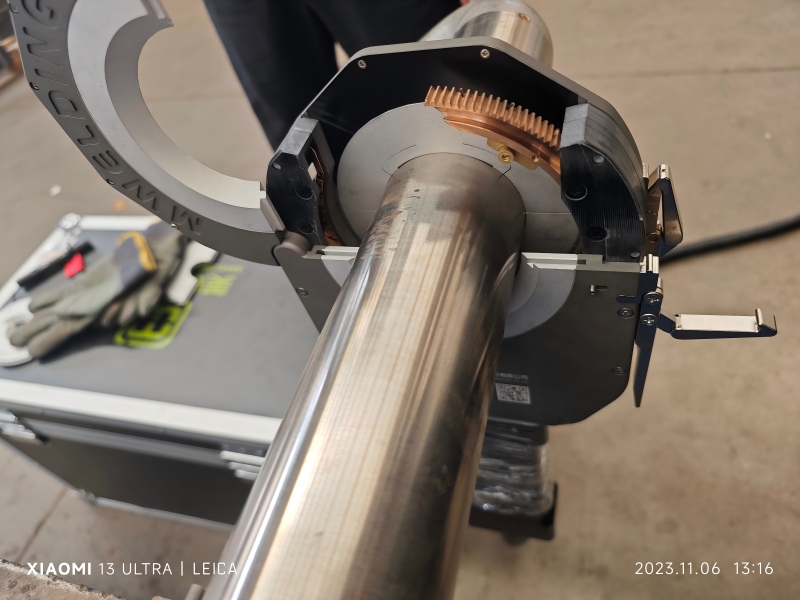

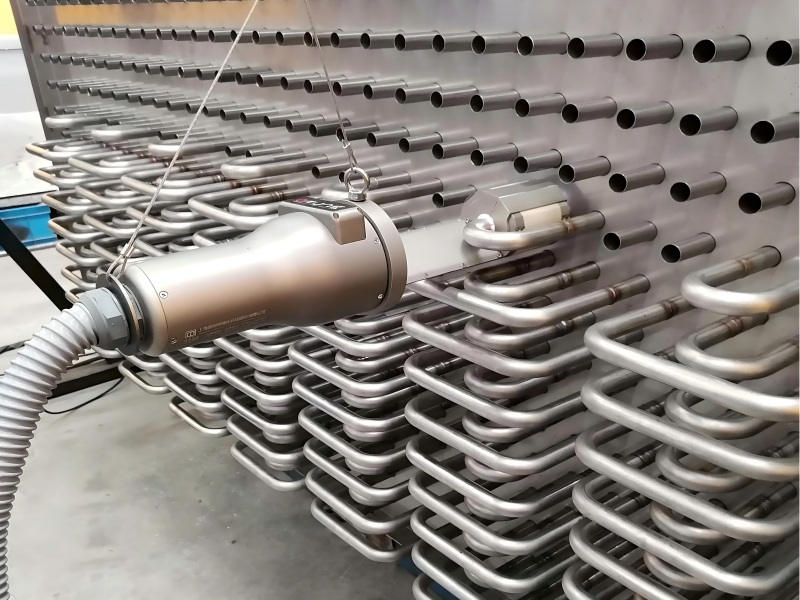

Our closed-head systems ensure flawless tube-to-tubesheet joints with controlled arc parameters and synchronized wire feeding. Every weld is automatically documented for full traceability — guaranteeing repeatable results across large-scale production.